It wasn’t all that long ago that, if you were in the market for a gas furnace, there really wasn’t that much to choose from.

Within the last few years, however, technological advances in gas furnace design have given homeowners a myriad of choices, all of which are intended to increase indoor comfort while decreasing heating costs.

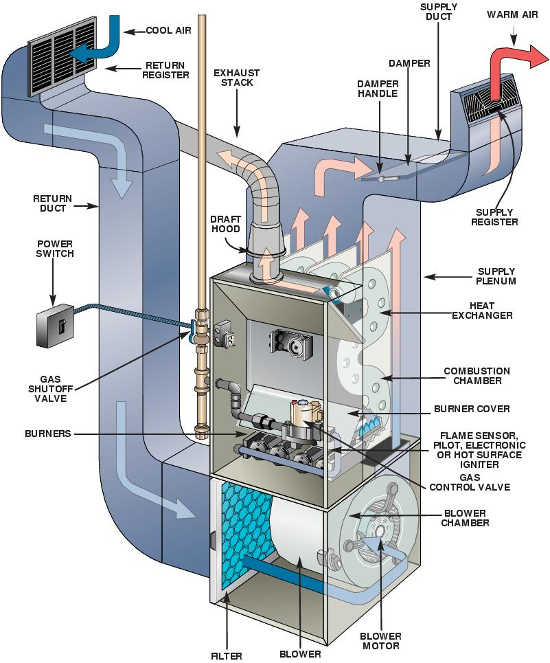

Regardless of the design, all gas furnaces consist of four main components: a burner, a heat exchanger, a blower and a vent pipe or flue.

The burner is where the gas is delivered and burned. Nearly all gas furnaces today use an electrical ignition device instead of a constantly burning pilot light to ignite the gas.

Said device works like an automobile spark plug. Whenever the thermostat calls for heat, the ignition device instantly lights the burners. By not using any gas between ignition cycles, this component conserves the fuel previously used by a pilot light.

The heat exchanger transfers the heat produced from the burning gas to the home’s distribution system. They come in a variety of shapes, with a serpentine configuration being one of the most efficient and popular.

When looking at gas furnaces, the experts recommend that the heat exchanger is crimped instead of welded together. The new crimped method helps eliminate heat stress cracks that might occur.

The blower is a large fan that moves the heated air through ducts to the location in the home where it is needed.

The vent pipe or flue exhausts the gaseous byproducts of combustion to the outdoors. Depending on the type of furnace, venting can take place through the chimney or through a plastic pipe out the side of the house.

These four components form the basis of three types of gas furnaces: a conventional warm-air furnace, an induced draft furnace, and a condensing furnace.

Conventional warm air furnaces burn natural or propane gas to provide heat to the heat exchanger; indoor air flows around the heat exchanger to be heated and then circulated throughout the house through ducts. Other ducts return air that has cooled to the furnace to be reheated and re-circulated. Additional air is drawn into the flue for venting purposes. This air mixes with the hot exhaust gases and exits through the chimney.

Induced draft furnaces are similar except for their venting method. Conventional furnaces draw air through an opening in front of the furnace and at the flue to create a natural draft. Induced draft furnaces use a fan to draw the combustion products into the flue. This artificially created draft increases the efficiency of the furnace.

A condensing furnace is named such since it contains a second heat exchanger that condenses water vapor in the hot flue gases, thereby extracting additional heat for the home. Because the resulting flue gases are at a very low temperature, they can be vented directly outdoors through a plastic pipe that can run through a side wall. A drain disposes of the condensed water. Condensing furnaces are among the most efficient on the market.